The global quest to mitigate the effects of climate change has placed hydrogen at the center of energy transition strategies in recent years. In Brazil, a country with one of the cleanest energy matrices in the world and significant potential for biogas production, the union of academic research and high-performance industrial automation is yielding promising results.

A prime example is the inauguration of the BioSiSH2 reactor, an advanced pilot plant developed by Lobo Industrial Solutions for the Environmental Technology Laboratory (LabTam) at the Federal University of Rio Grande do Norte (UFRN) in Brazil.

This project goes beyond delivering complex scientific infrastructure: it represents a milestone for Brazilian technological sovereignty. Funded by the National Council for Scientific and Technological Development, the Ministry of Science, Technology and Innovation, and the National Fund for Scientific and Technological Development, the BioSiSH2 reactor is formally part of the Brazilian System of Hydrogen Laboratories (SisH2-MCTI).

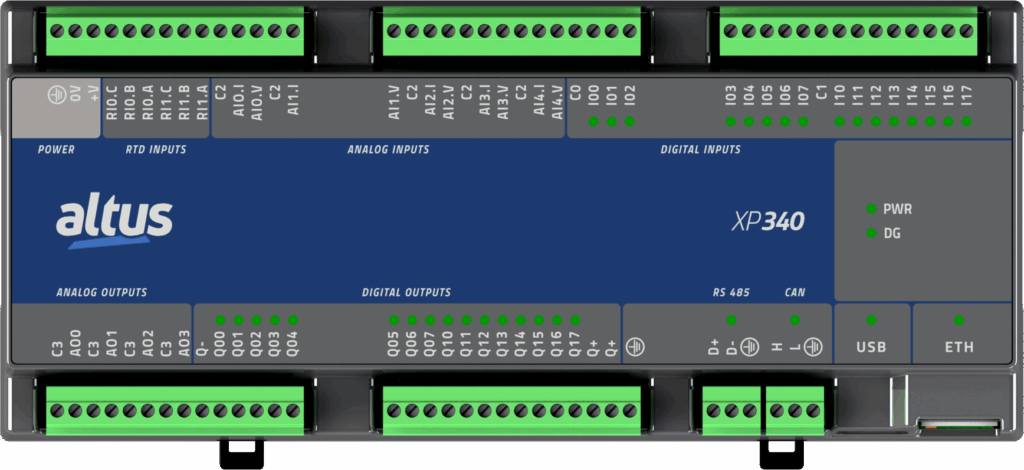

In this context, the choice of automation technology was decisive for the success of the application, requiring robust solutions, high precision in controlling sensitive chemical processes, and a supervisory interface capable of transforming raw data into knowledge. To meet these demands, Lobo Industrial Solutions developed the application using Altus’ XP340 PLC and BluePlant SCADA software. Learn more about this project in the following paragraphs.

The challenge of producing hydrogen from biogas

The production of renewable hydrogen from biogas involves significant thermodynamic and operational challenges. The core process of the BioSiSH2 plant is the Dry Reforming of Methane (DRM), a highly endothermic reaction that occurs at high temperatures, typically between 700°C and 900°C.

The chemical equation for this process can be represented as: CH4+CO2→2H2+2CO

In this reaction, methane (CH4) and carbon dioxide (CO2), the two main components of biogas and potent greenhouse gases, are converted into synthesis gas (syngas). The efficiency of this conversion depends on extremely precise control of the reactor temperature and feed flow rates. Thermal oscillations not only reduce yield but can also lead to the rapid deactivation of catalysts due to coke formation (solid carbon deposition), which compromises research integrity and increases operational costs.

Beyond reforming, the pilot plant integrated a synthesis module responsible for transforming the syngas into higher-value hydrocarbons, such as synthetic fuels and methanol. This second stage requires controlled pressures and temperatures managed by highly complex PID (Proportional-Integral-Derivative) control loops. Instability in any of these parameters can result in unwanted side reactions or safety risks, given that both methane and hydrogen are highly flammable and explosive.

This scenario immediately imposes rigorous safety and regulatory compliance requirements, as operating an advanced chemical process plant within a university environment demands high standards of protection. The project had to meet the requirements of brazilian standards NR-12 (Safety in Machinery and Equipment) and NR-13 (Boilers, Pressure Vessels, Piping, and Metallic Storage Tanks).

In this context, automation ceased to be merely a productivity tool and took on an essential role in life safety. It was indispensable to have a system capable of executing immediate safety interlocks in situations such as leaks, overpressure, or heater failure.

The core technological solution: the XP340 controller

To lead this complex operation, Lobo Soluções chose the XP340. This PLC stands out by delivering the performance of large-scale controllers in a compact and IoT Ready design, making it ideal for applications that require high processing capacity in small spaces.

Since one of the greatest challenges faced by Lobo Soluções was the integration of more than 230 components in the pilot plant, the XP340 simplified this process by offering multiple communication interfaces, such as Ethernet and RS-485 ports.

The system architecture made extensive use of the Modbus RTU protocol for communication with slave devices on the network, enabling reliable readings from instruments by different manufacturers within a single infrastructure. Furthermore, support for the OPC UA protocol ensures that the system is prepared for future integrations with cloud platforms and Big Data analytics solutions, if necessary.

The XP340 is equipped with a high-speed 32-bit ARM processor, capable of processing complex logic and multiple PID loops simultaneously. In the LabTam application, the controller manages the electric heating resistors of the reactors, where response time and precision are vital to avoid thermal “overshoot” that would damage the catalysts. The hardware’s robustness allows the execution of up to 16 parallel tasks, ensuring that safety routines have absolute processing priority over data acquisition and processing tasks.

See how the main features of the XP340 act directly on the operation control:

| XP340 | Benefit in the reactor |

| Analog inputs | Accurate reading of temperature sensors (RTD) and pressure transmitters. |

| Analog outputs | Proportional control of valves and heating power. |

| Modbus RTU and TCP protocol | Integration with flow meters and gas analyzers. |

| Integrated firewall | Cyber protection of research data against external threats. |

| WebVisu support | Remote monitoring of the reactor without the need to access the control room computer. |

The high I/O density of the XP340 was also a differentiator for the project. In a single module, the controller gathers 16 digital inputs, 16 transistor digital outputs, 5 analog voltage/current inputs, 2 analog inputs for RTD temperature sensors, and 4 analog outputs. This configuration enabled the integration of most field instruments directly into the central controller, reducing cabling costs and minimizing potential system failure points.

The ruggedness of the application is also due to the controller’s memory capabilities:

| Memory | XP340 | Function in the reactor |

| Program memory | 8 MB | Storage of all control and safety logic. |

| Symbolic variable memory | 6 MB | Management of thousands of internal and communication tags. |

| Retentive memory | 7,5 KB | Preservation of setpoints and states in case of power failure. |

| User file memory | 8 MB | Storage of experiment recipes and local logs. |

These specifications ensure that the PLC does not suffer from latency, maintaining a stable cycle time even when the Modbus RTU network is operating at maximum load.

Distributed engineering and intuitivity with BluePlant SCADA

If the XP340 is the plant’s brain, BluePlant acts as the nervous system and memory of the BioSiSH2. Developed on the Microsoft Windows Presentation Foundation (WPF) platform, it offers a modern and intuitive interface so that the plant can be operated in an assisted, safe, and efficient manner.

The use of WPF/XAML technology in BluePlant enables the creation of resolution-independent synoptics and high-quality graphics, even on screens with a large number of dynamic objects. This results in intuitive screens that allow real-time monitoring of reagent flow (CH₄, CO₂) and product formation, featuring animations that indicate valve opening states and heater operation.

BluePlant also enables distributed engineering, where multiple developers can work on the project simultaneously via the network, accelerating plant commissioning. Furthermore, its native 64-bit client-server architecture ensures stability for long-term operations.

The critical role of the historian and alarm management

In scientific research, data is the most valuable asset. For this reason, BluePlant‘s advanced historian can be configured to continuously record every process variable in SQL databases, ensuring the traceability of experiments.

Unlike traditional systems that use interpreted languages such as VBA or VBScript, BluePlant is based on compiled .NET languages (C# and VB.NET). This results in greater stability, performance, and security when recording logs, essential requirements for environments that demand data integrity and reliability over time.

Additionally, BluePlant’s alarm management is structured to ensure that no operational deviation goes unnoticed. To achieve this, alarm groups can be defined with different severity levels, allowing for a proportional response to each situation:

- – Critical: These trigger safety interlocks and automatic purge routines, acting immediately to eliminate hazardous conditions;

- – Warnings: These notify users of trend variations that could affect reaction quality, allowing for preventive adjustments before more severe deviations occur;

- – System Events: These record the entire operation history and all user actions.

| BluePlant functionality | Added value |

| Integrated SQL Historian | Traceability of every experiment. |

| Trend Graphics (Trends) | Visual analysis of temperature and pressure stability. |

| Managed .NET Software | Protection against memory failures and increased reliability. |

| Server Redundancy | Guarantee that supervision does not stop even in the event of hardware failure. |

| Web and Mobile Clients | Possibility to monitor the plant from anywhere. |

From prototype to the consolidation of national technology

What began as an academic demand from UFRN evolved into a project of national relevance upon its official integration into the Brazilian System of Hydrogen Laboratories (SisH2-MCTI), establishing itself as a concrete example of innovation applied to the Brazilian energy transition.

According to Ciro Lobo, the experience with Altus was positive from the very first contact. The agile and transparent quoting process, combined with fast and highly specialized technical support, allowed Lobo Soluções to focus its efforts on the intelligence and complexity of the chemical process, while Altus ensured the stability, reliability, and performance of the automation platform. “National technology, with an excellent cost-benefit ratio and high availability, was a decisive factor,” he highlights.

The integrated application of the XP340 PLC with BluePlant SCADA resulted in significant gains for the project, including:

- – Significant increase in safety, with reliable interlocks and automatic action in critical situations;

- – High operational stability, essential for conducting long-duration trials without interruptions;

- – Greater precision in PID loop control, allowing for fine and repeatable adjustments in chemical reactions;

- – Reduction of operational errors, provided by an intuitive and operator-oriented SCADA interface;

- – Increased reliability of experimental data, ensuring the quality, traceability, and scientific validity of the results obtained.

With the consolidation of this project, Altus reaffirms its position as a strategic partner in the renewable energy sector, delivering solutions that combine next-generation supervisory software with robust control hardware. The BioSiSH2 reactor undoubtedly represents a major step toward a Brazil that is increasingly sustainable and technologically independent.

The trajectory presented reinforces that success in complex applications depends on choosing partners capable of offering not only products, but a complete ecosystem of support, ease of development, and cutting-edge technology. The energy transition demands precision, and at LabTam, that precision has a name: Altus.