- Segments

- Manufacturing Industry

- Automotive

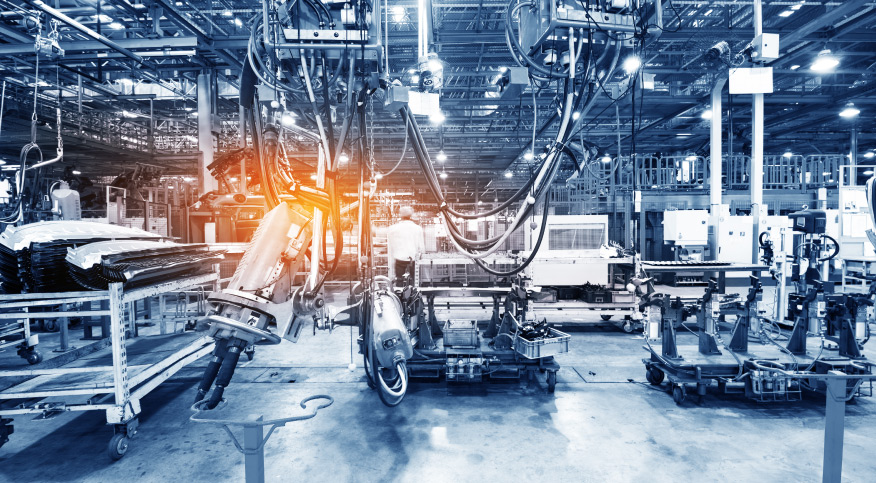

Integrated systems for the Automotive Industry

Discover our solutions to integrate the processes in your smart assembly lines

The processing capacity available in the Nexto Series programmable controllers allows you to create complex, high-precision applications capable of adding safety to line operations. With various embedded communication features, Altus PLCs can be used both as control and command centers for machines and devices and as gateways between systems.

Request an assessment

Do you want to implement your current project with us? We will be happy to advise you!

Projects and solutions for the sector

Volkswagen Brazil

Volkswagen Brazil turned to Altus solutions for the technology needed to modernize its assembly lines.

Heavy vehicle manufacturer

Modernization of the control and supervision system for the test line at a major heavy vehicle manufacturer.

Autoclave Supervisory System

Altus developed Vipal's new autoclave system for controlling autoclaves used by authorized retreaders.

Vehicle manufacturer

Altus products were chosen for the modernization of the system to improve water reuse.

Our solutions for this industry

Total control from assembly to vehicle completion

The programmable controllers developed by Altus can be used in the most diverse sectors of the automotive industry. In the component assembly process, our PLCs coordinate every stage, from selection to positioning and fastening of components, ensuring the precision and speed necessary to meet automotive market demands.

Then, during welding, they interact with welding robots to ensure perfect and consistent joints, resulting in final products of superior quality and exceptional durability. In the finishing stage, our controllers adjust critical parameters such as pressure, temperature, and application time, providing a uniform, resistant, and aesthetically flawless paint job on every vehicle.

Technology to ensure the quality and efficiency of your business

The products developed and marketed by Altus can also operate in the meticulous monitoring and control of every stage of the inspection process, ensuring that each vehicle meets the highest quality and safety standards.

Furthermore, they can be applied to material handling and transport, optimizing production flows by coordinating the precise and efficient movement of parts and components. This not only increases operational efficiency but also reduces costs and production time, bringing tangible benefits to your business.

Control and monitoring of handling and transport processes

With a powerful processor and onboard I/O points, the NX3008, the most advanced CPU model in the NX Series, has the capacity to coordinate the movement of parts and components in a precise and dynamic manner. This processing power allows controlling conveyors, elevators, belts, winches, doors, pneumatic pistons, and other devices. This enables the controller to perform handling and transport operations efficiently, reducing cycle times and increasing production capacity.

Furthermore, NX Series PLCs enables for integration with logistics and automation systems, such as AGVs (Automated Guided Vehicles) and automated transport systems. This enables even more efficient and safe material movement, eliminating dependence on manual operations and reducing the risk of errors.