Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

Supervision and Control System

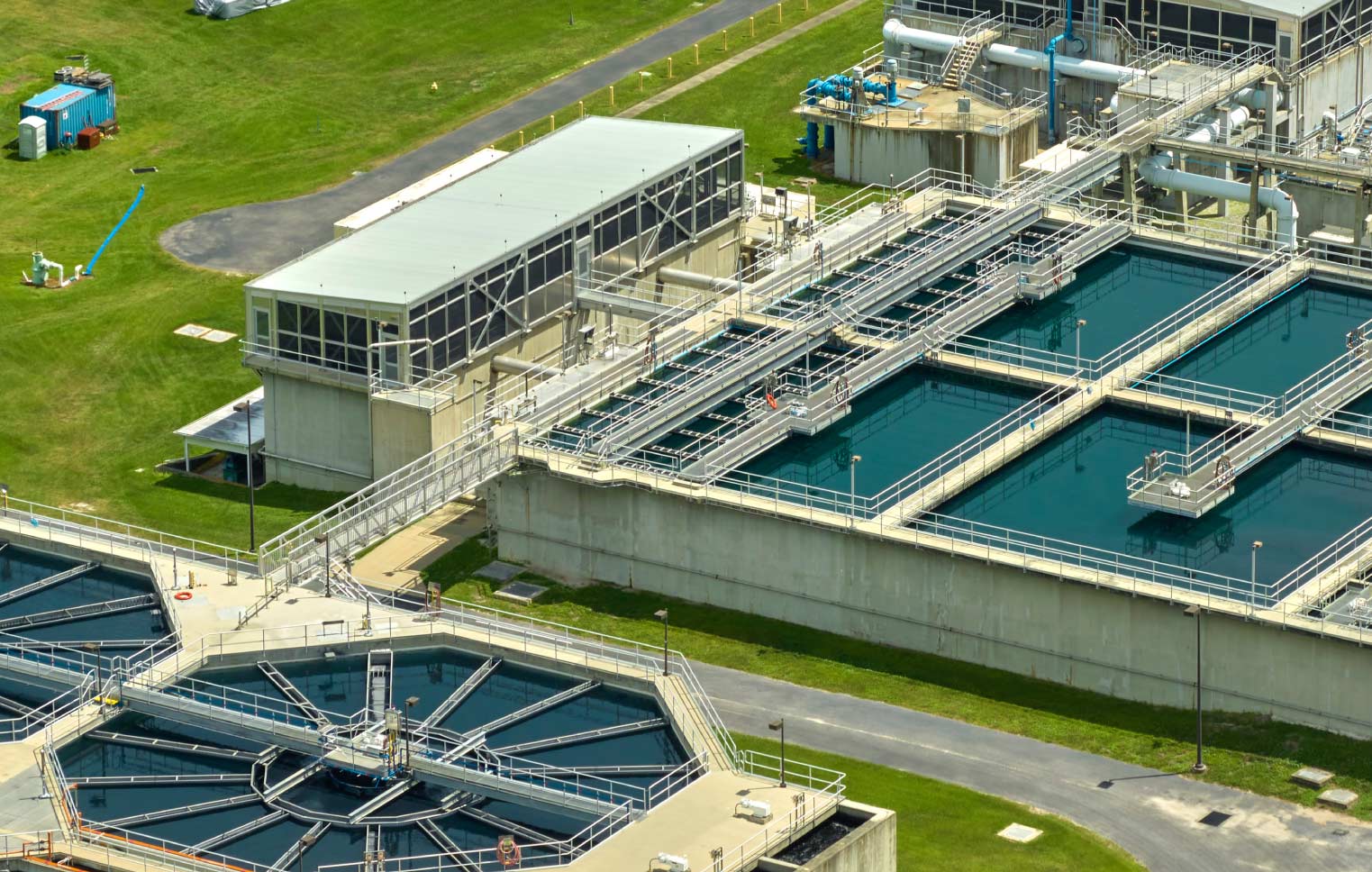

Altus acted as a technology supplier for Comápice Equipamentos e Sistemas Ltda., being responsible for the development of the Supervision and Control System for the Barra da Tijuca Wastewater Treatment Plant in Rio de Janeiro, for the end client CEDAE (Companhia Estadual de Águas e Esgotos).

Streamlined data management with responsive dashboards, providing real-time, up-to-date system information

The solution enables remote supervision and operation of the plant, minimizing risks for operators

The architecture makes it easier to track equipment performance over tim

This solution relies on Altus programmable controller technology for data collection and processing at the facility

The Automation System offers several important benefits, including the ability to quickly access consolidated maintenance data such as operating times of pumps, grids, and blowers, improved planning and operational control across the plant, reduced operating costs thanks to automated controls that require fewer operators per shift, and increased reliability of the installed equipment.

The Altus solution enables a highly effective preventive maintenance system, making it easier to track equipment performance over time. The system also provides access to equipment diagnostics, simplifying issue identification and supporting scheduled equipment rotation.

The solution delivered by Altus includes the following equipment and services:

- AL and Ponto Series Programmable Controllers (Profibus DP remote units))

- Ethernet Network Interface (AL-3405 card)

- Profibus-DP Master Network Interface (AL-3406 card)

- Consulting services for system architecture design

- raining in programming and maintenance of programmable controllers

The Altus PLC that manages the system is connected to the CCO (Operations Control Center) via an Ethernet TCP/IP network. Some remote units are connected through a PROFIBUS-DP network using optical cables, while others use standard cables.At the CCO, operators can monitor all subsystems, analyze each unit in the process, and intervene in real-time by turning equipment on or off and adjusting control setpoints by clicking on icons within the configured screens and interfaces.

© 2026 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.