Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

Control System for Hydrogen-fueled Vessels

Responsible for building catamarans and ships in the Washington area, the All American Marine shipyard found in Altus the technology needed to modernize the automation system of its fleet of boats and develop the first hydrogen-powered catamaran in North America and the first in the world to operate commercially.

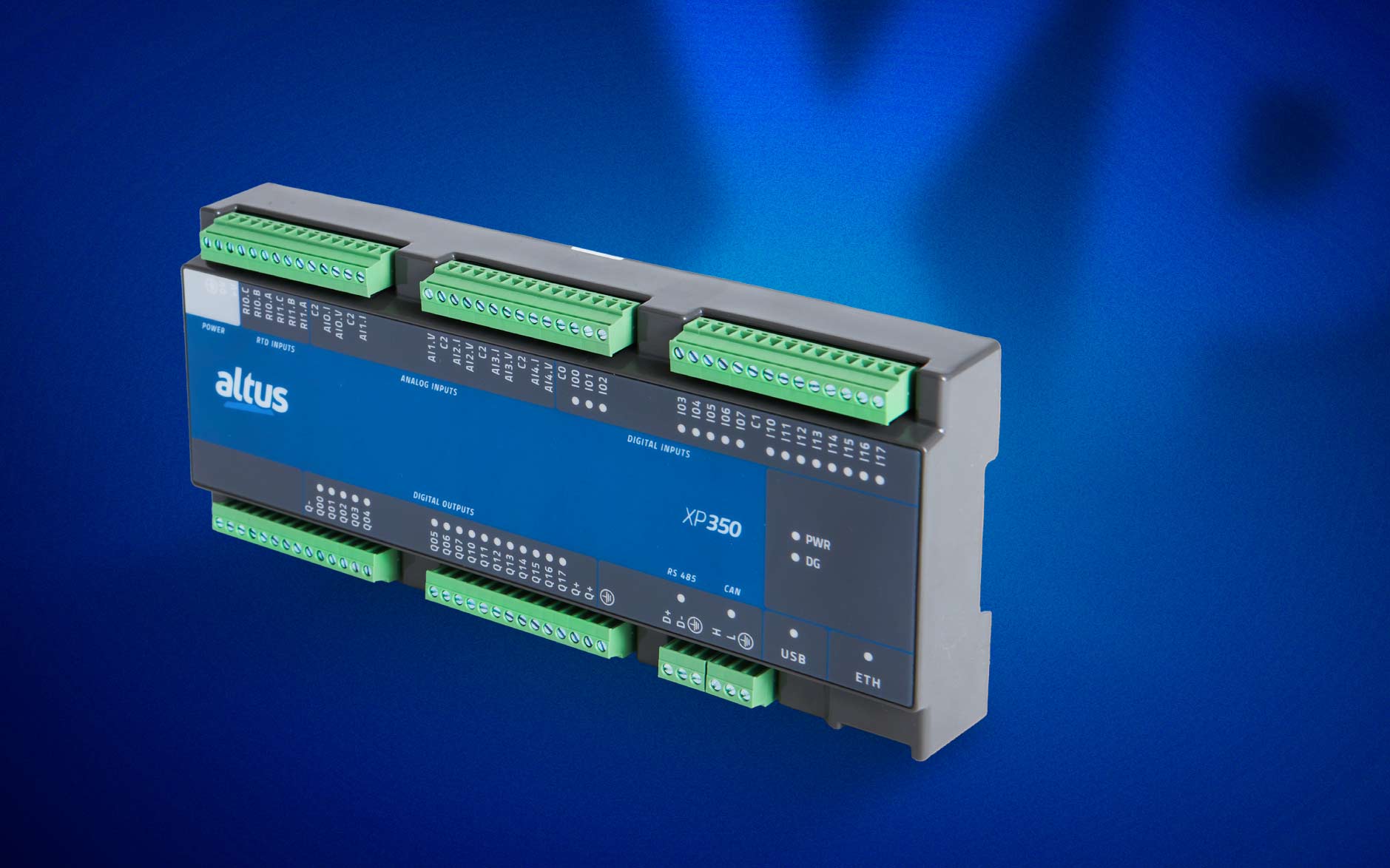

Monitors operational parameters via digital and analog sensors, capturing data on the vessel's condition

The system’s extensive range of communication interfaces and protocols enables the PLC to connect seamlessly with a variety of smart devices

With built-in analog interfaces, the solution requires minimal engineering investment for system configuration, reducing overall costs

All PLCs in the XP Series comply with Det Norske Veritas safety standards and are DNV certified.

The system architecture includes five XP315 controllers, part of Altus’s IoT-ready line, and a 15” HMI from the X2 Series. Four of the controllers are housed in isolated cabinets in the Motor Control Centers (MCC), located next to the fuel cell room and in each hull. They manage the drivers that control the onboard pumps and exhaust fans via a CANopen network. These controllers also collect data from sensors monitoring system variables

The fifth PLC, along with the HMI, is located on the bridge. Both the MCC controllers and the bridge’s Xpress PLC are connected to the X2 HMI through an Ethernet network, using the OPC UA protocol for communication.

To ensure these activities are performed as expected, it is essential to monitor several indicators, including internal temperature, bilge and tank levels, hydrogen cell cooling, backup, shutdown, system status, and monitoring. With high speed and a high reliability index, the XP Series programmable logic controllers were the chosen solution to compose the control system and guarantee the operability of these processes.

To increase their robustness, XP products also undergo tropicalization, essential for equipment installed on vessels. Furthermore, all PLCs in the Xpress family comply with Det Norske Veritas safety standards, possessing DNV Type Approval certification, making them fully ready for use in marine applications.

Thanks to its compact design and high I/O point density, the Nexto Xpress allowed the client to place a controller in each MCC cabinet to manage auxiliary loads, significantly reducing the need for wiring between the engine room and the bridge. This led to considerable cost savings in the project’s automation budget.

Dave Bechtel, managing partner of Bluefin Marine, comments that the communication capabilities of the XP PLC were one of the key factors in choosing it as the control solution for the application. "The diversity of communication interfaces and protocols available in the product is very interesting, enabling communication with different intelligent devices," says Dave.

Another advantage of Altus IoT-ready PLCs is the cost savings in development. With built-in analog interfaces, the system requires less engineering investment, resulting in a high-performance solution with optimized cost efficiency.

© 2026 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.