Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

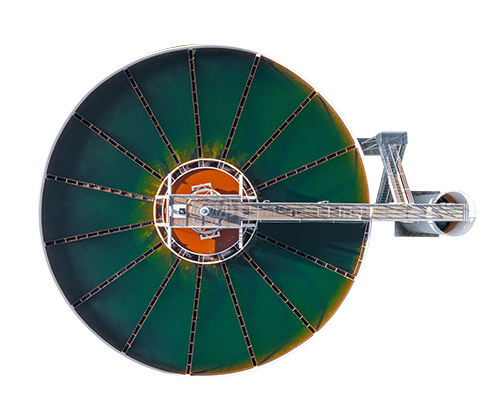

Sludge dewatering system

Altus was responsible for specifying and developing the automation project for the sludge dewatering system at the Novo Mundo Wastewater Treatment Plant, a project integrated into the Tietê River Depollution Program, conducted by Sabesp.

With this project, Altus reinforces its presence in the environmental sanitation sector, delivering highly reliable national technology to initiatives that promote the recovery of water resources.

Streamlined data management through real-time process reports, providing up-to-date information on the system

The solution enables remote supervision of the dewatering process, minimizing risks for WWTP operators

Faster detection of faults and incidents with clear, concise, and precise alarms

This solution relies on Altus programmable controller technology for data collection and processing at the facility

One of the major benefits of the Automation System is the ability to quickly access consolidated data crucial for maintenance activities, such as:

- Management planning and control of operations at the plant

- Reduced operating costs, as automated controls require fewer operators per shift

- High reliability of installed equipment

Altus’ solution offers a comprehensive range of equipment and services tailored to meet the specific automation and process control needs.

The system includes programmable controllers mounted in panels and a gateway for the process network. It also covers the specification and development of PLC application programs, electrical design, and panel assembly, as well as platform integration, start-up, assisted operation, and PLC programming training.

Implementing this solution delivers multiple benefits, enhancing the overall efficiency and effectiveness of the wastewater treatment plant.

Key advantages include continuous monitoring of the dewatering process, allowing operators to track the system's status in real-time, as well as alarm notifications that alert operators to any anomalies or issues. The system also ensures control over the equipment, making sure everything operates smoothly and efficiently..

Additionally, the solution allows for the generation of detailed process reports, providing valuable insights into the system’s performance. The solution integrates seamlessly with the equipment controlling the filter presses, optimizing the entire operation.

Altus demonstrates its commitment to delivering cutting-edge technology and high-quality services, contributing significantly to the optimization and automation of industrial processes.

© 2026 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.