Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

High-performance Control System

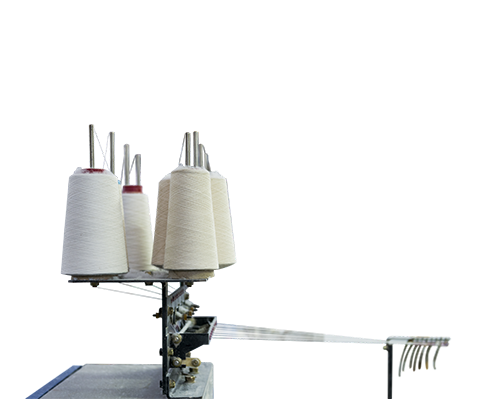

A prominent Brazilian company in the national textile market found in Altus the ideal solution to maintain the operational stability of its yarn and fabric finishing unit.

The solution fully integrates with existing systems, eliminating the need for parallel controls

The embedded technology in this solution delivers highly accurate data throughout the process

The speed and processing power of the Nexto PLC delivered a significant performance boost

The Nexto PLC’s built-in features provide quick, real-time access to diagnostics and reports

The high technology used and its advanced scalar architecture, which allows easy integration with the most traditional supervisory systems, make the NX Series programmable controllers the ideal solution for the project. The equipment in the series has an internal bus based on deterministic Ethernet with the possibility of expansion to up to 24 remote racks, each with a capacity of 24 modules, totaling 320 I/O points per rack.

The NX Series also features MasterTool, a complete tool for programming, debugging, configuring, and simulating user applications. With a modern and customizable, object-oriented interface, the software allows the development of advanced functions such as process variable manipulation, recipe management, PID blocks, and timers.

© 2026 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.