Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

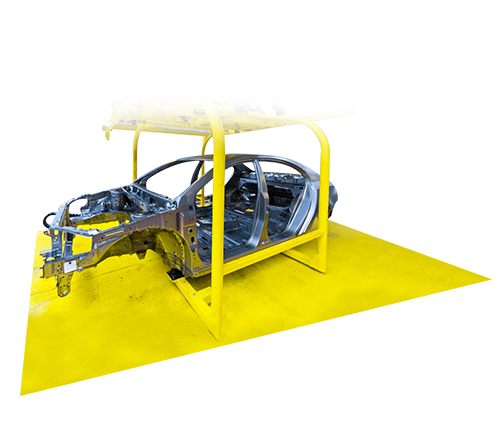

Modernizing the Control and Supervision System

Altus products were chosen by a world-leading automotive manufacturer to modernize its water reuse control system at one of its industrial plants.

The system features NX3030 CPUs running in hot standby redundancy mode

The application is powered by robust Nexto CPUs acting as remote units, enhancing the system’s control capabilities

The PLC’s seamless communication with field devices enhances decision-making speed for the management team

The speed and processing power of the Nexto PLC delivered a significant performance boost

To meet the demands of this project, Nexto programmable controllers were recommended. With high-speed processors and no moving parts, the products offer greater reliability and extended uptime.

Their multiprocessing capabilities bring features typically found in DCS systems. The NX Series PLCs support both graphical and textual programming languages in compliance with the IEC 61131-3 standard. One standout feature is the graphical FBD (Function Block Diagram) language, which enables the system to be broken down into functional blocks, making maintenance easier and allowing for the use of different programming languages within each block, enhancing programming flexibility.

Another key advantage was the use of pre-built libraries in the MasterTool IEC XE software, which significantly reduced development time. In addition, communication via PROFIBUS-DP, a common feature in these applications, allowed for seamless integration with devices from multiple manufacturers.

© 2026 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.