Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

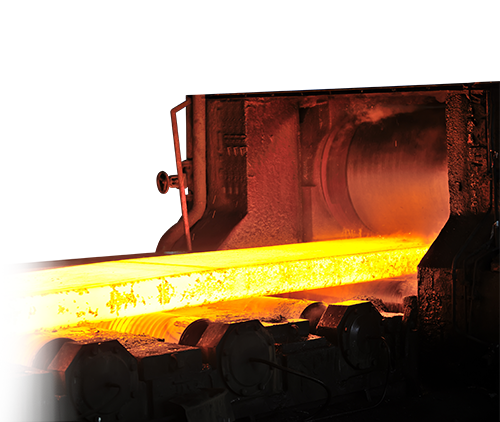

Boiler Control System

Altus provided the automation technology for the development of the new Boiler Control System at one of Usiminas' manufacturing plants, one of the largest companies in the Brazilian steel sector, generating savings and increased productivity for the company.

The energy generation optimization achieved through this project saves Usiminas approximately US$ 450,000 per month

The embedded technology in this solution delivers highly accurate data throughout the process

The system also enhances the centralization of all data related to resource use

With a range of online diagnostics and alarms, the system enables remote monitoring, ensuring continuous oversight

The system is controlled by four Altus programmable controllers, connected via an Ethernet network with CPU and I/O module redundancy.

Supervision is carried out from a dedicated Supervisory Station, with all PLCs linked to it through Altus AL-3405 communication modules over Ethernet/TCP-IP (IEEE-802.3), as well as the optical transceivers and repeaters used in the project.

The system also features a real-time multitasking processing module, which handles communication with two single-loop controllers for precise boiler temperature control.

The system includes 784 digital and analog input/output points, all operating in redundancy mode, along with the process control CPUs. These operate within an Ethernet TCP/IP network using fiber optics.

Additionally, the system features remote supervision capabilities for enhanced monitoring and control.

© 2026 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.