- Solutions

- CSS Offshore

CSS Offshore:

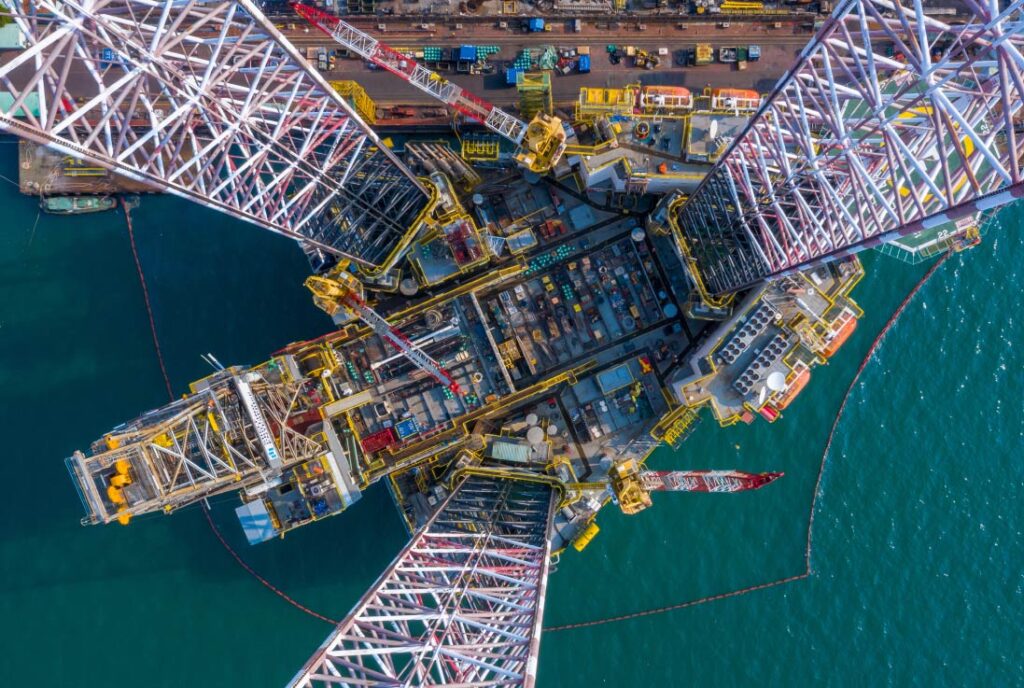

High-availability and safety control solution for offshore platforms

With over 30 years of experience in the Oil and Gas sector, Altus brings the expertise and advanced technology needed to deliver a customized Control and Safety System (CSS) for offshore platforms.

Request an assessment

Do you want to implement your current project with us? We will be happy to advise you!

Automated processes with the Control and Safety System (CSS)

The CSS consists of three key subsystems: control and monitoring of production and utilities, emergency shutdown (ESD), and fire and gas detection.

In natural gas export processes, the CSS manages pressure, temperature, and flow measurements, while also overseeing equipment like PIG launchers and receivers, heat exchangers, flow computers, control and safety valves, and the chemical injection of ethanol into the export pipeline of each FPSO.

Learn about the main features of the Altus Control and Safety System.

High level of availability

Each automated system has 2 programmable controllers operating in a high-availability, hot-standby mode. If the main CPU becomes unavailable, the redundant standby equipment automatically takes over control of the industrial process

Performance increase

Convergence of control systems, user-friendly visual interface, real-time graphical reports, complete integration with corporate systems, updated and highly versatile technology, high level of redundancy with hot-swapping of modules.

Automated process modules

Control of subsea equipment, oil separation and treatment, gas dehydration and compression, electricity generation, sulfate removal from water and its injection, oil unloading, and natural gas export from exploration platforms.

Distributed Systems

The high-availability system requires the use of thousands of I/O points distributed across various conventional or pressurized remote locations, interconnected to the instrumentation of the process modules via PROFIBUS-DP and HART field networks.

Services and equipment provided with the Altus Control and Safety System.

Services included with the CSS

– Comprehensive project design, detailed engineering, development of controller logic, and screen layouts for supervision

– Preparation of technical documentation and manuals

– Design of controller panels, remote I/O panels, server panels, and operator stations

– Development of controller applications using MasterTool IEC XE programming software

– Creation of SCADA interface screens with Wonderware InTouch® software

– Integration with package systems, instrumentation, and field equipment, as well as fiber optic splicing

– Training on products, maintenance, engineering, and CSS operation

– Configuration and integration of asset management systems

– Onshore and Offshore commissioning at the shipyard, and assisted operation

Equipment included with the CSS

– Pressurized remote I/O panels for installation in process modules (hazardous zones)

– Remote I/O panels for indoor environments (control rooms or engine rooms)

– Control panel

– Server panel, network switches, and operator stations

– Engineering station and two printers

– Fiber optic cables (two-pair)

– Fiber optic cables (three-pair)

Guaranteed performance and high availability with the Nexto NX Programmable Controllers

The NX Series of PLCs feature advanced, high-speed technology that ensures reliability and connectivity, enhancing your business’s productivity. With integrated Distributed Control System (DCS) functionalities, the NX Series offers features like hot swapping, CPU redundancy, I/O expansion, and a scalable architecture built on deterministic Ethernet, supporting all stages of the application lifecycle.

For applications that cannot be stopped, such as O&G, Sugar & Ethanol, Steelmaking systems, among others, the NX Line has support for CPU redundancy, a feature that practically eliminates the need to stop the system for maintenance.