Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

Control system for soybean Oil Extraction Plant

Altus was entrusted with the development and implementation of the control and supervision system for the soybean oil extraction process at the company’s facility.

The solution enables remote supervision and operation of the plant, minimizing operational risks for the workforce

Swift detection of system faults and incidents, thanks to the implementation of precise, actionable diagnostics

An open architecture system, utilizing widely recognized communication protocols (Profibus-DP, HART, and Modbus TCP)

The PLC’s seamless communication with field devices enhances decision-making speed for the management team

The developed application uses three Profibus networks: one redundant network with remote I/O units from the NX Series, and a simple network for controlling inverters and soft starters. While the redundant network has 13 redundant remote units, the other controls the inverters and soft starters with 99 items, including 27 inverters and 72 soft starters.

The entire project encompasses 10 automation panels with a total of 13 columns (PNs). The scope of the project also included commissioning, startup, assisted operation, and training for both maintenance and operational teams.

The system relies on BluePlant HMI/SCADA software to supervise key processes such as Warehouses 2 and 3, Laminators 1 and 2, Screeners, Preparation, Flow Scales 1 and 2, Dryer, and Pier Towers.

With 83 monitoring screens, the SCADA system manages over 150 motors that drive product and raw material movement within the plant and during ship loading operations at the pier.

The software provides plant managers and operators with remote access to the system, allowing them to collaborate in real-time with field technicians, streamlining overall plant management.

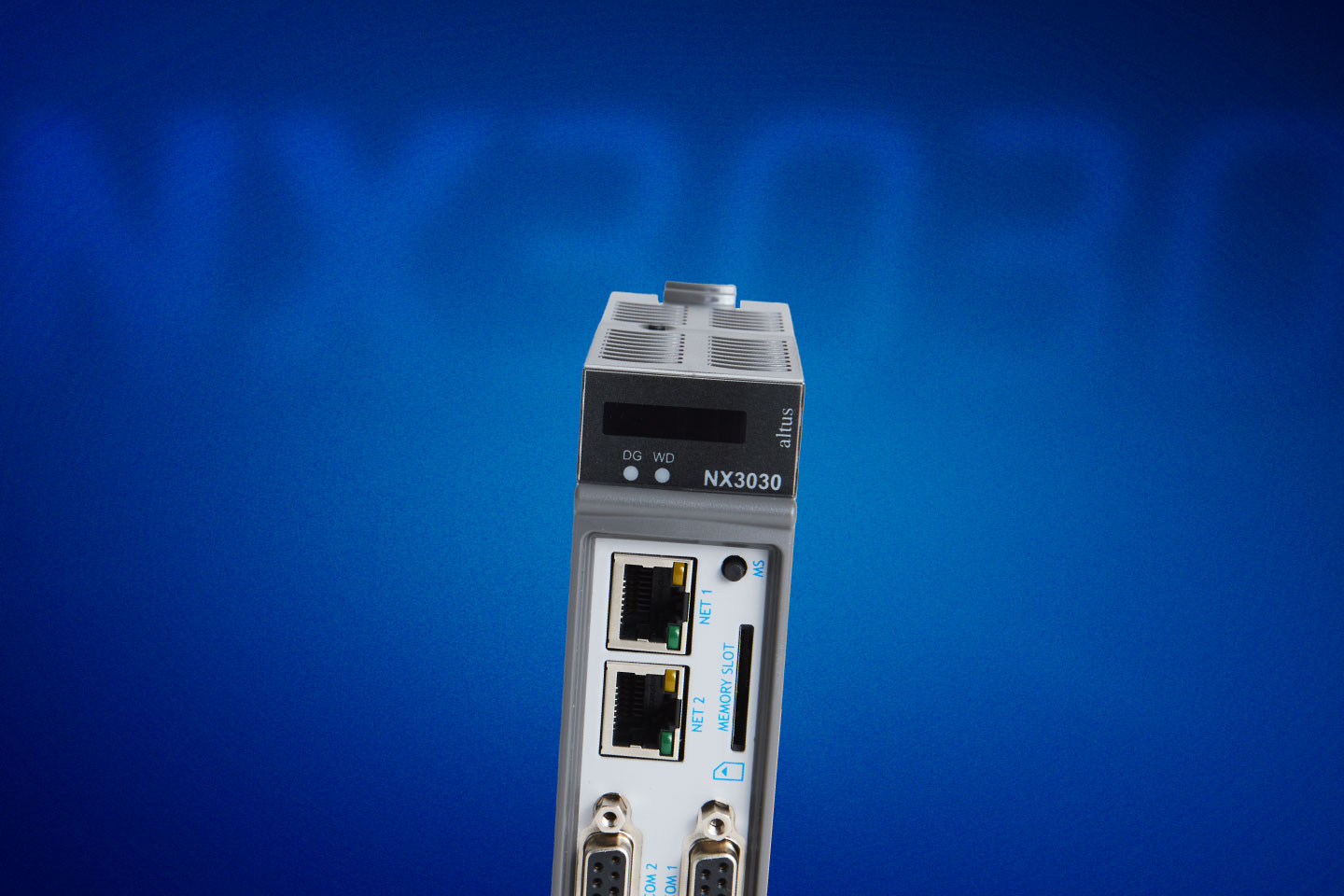

The developed application utilizes the NX Series programmable controllers as the central component of the unit's control system. The high technological potential of Nexto products qualifies them to operate large numbers of remote points and racks, as well as to control projects such as water treatment in a distributed and redundant manner.

The system features a redundancy setup with two NX3030 CPUs — one primary (active), responsible for real-time control, and a standby backup unit that continuously monitors the performance of the primary CPU.

Caso alguma falha venha a ocorrer e a CPU principal fique indisponível, o equipamento em stand-by assume o controle do processo de maneira automática, sem a necessidade de qualquer ação do operador e sem causar perdas à operação da planta. Essa troca de função entre os equipamentos é conhecida como switch-over.

© 2026 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.