Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

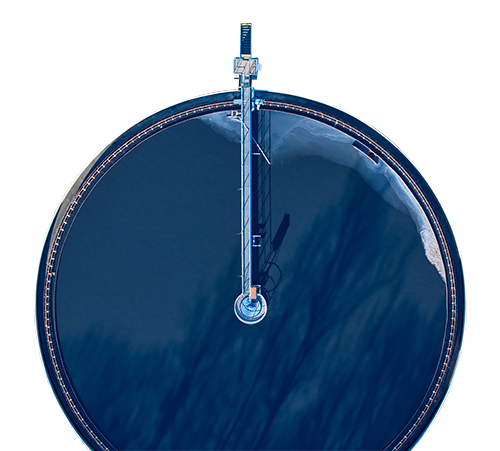

Supervision and Control Integration

Altus' Nexto System programmable logic controllers were chosen to comprise the new supervision and control system for Sabesp Santos' Control Center (CCO). With proven robustness in critical applications, the Nexto line of PLCs offers reliable performance and efficient communication, essential for integrated sanitation management.

With high data processing capacity, the solution allows for remote plant supervision and operation via the CCO, ensuring greater security, agility, and reliability in operations.

Streamlined data management with responsive dashboards, providing real-time, up-to-date system information

The solution allows remote supervision and operation of the plant, minimizing risks to operators

The architecture makes it easier to track equipment performance over tim

This solution uses Nexto programmable controllers for data collection and processing within the unit

Altus' NX Series programmable controllers were used to maintain the sanitation levels that Santos enjoys. With great technological potential, it is capable of controlling large numbers of I/O and communication points, as well as distributing control over projects such as sewage treatment and pumping in any location along the coast of São Paulo.

The controllers support communication with a wide range of devices and supervisory software. The use of open protocols is essential to ensure compatibility and integration with various systems. For instance, the MODBUS/TCP protocol operates as both a client and server within the CPUs.

The solution provided by Altus enables a highly effective preventive maintenance system, which helps track equipment performance over time.

It also gives access to equipment diagnostics, simplifying issue identification and supporting scheduled equipment rotation.

For this operation, two NX3020 units were used, with approximately 200 remote units connected, totaling more than 6,000 communication points. This project also developed logic that enabled the execution of logic loops in commands between the CPUs connected to the NX Series and the supervisory system that controls the process. This prevents any interference in the physical medium from altering any output command from the supervisory system before it reaches the remote unit.

Additionally, the CPUs, equipped with dual independent Ethernet interfaces, isolate the supervisory software from the company’s corporate network, reducing the risk of system vulnerabilities from potential viruses. Another key advantage of this project was the product’s compact design, which allowed for quick adaptation to the existing panels at the CCO without taking up too much space.

© 2026 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.